Robert F. Bourque, Ph. D., P.E.

Bourque Engineering LLC

Los Alamos, New Mexico USA

bob@rfbourque.net

505-412-0194

Chapter |

Title |

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

11 |

|

12 |

|

13 |

|

14 |

|

15 |

|

16 |

|

17 |

|

18 |

|

19 |

|

20 |

|

21 |

|

|

|

|

|

|

A Compact Pollution-Free

External Combustion Engine

with High Part-Load Efficiency

Previous Chapter | Next Chapter

20. Starting Time

Starting time is an important factor in the engine design. For example, a lower exhaust gas temperature would increase efficiency. But it would also increase Steam Generator mass. This would increase startup time because most of the energy in starting goes into heating the metal, not the steam.

|

|

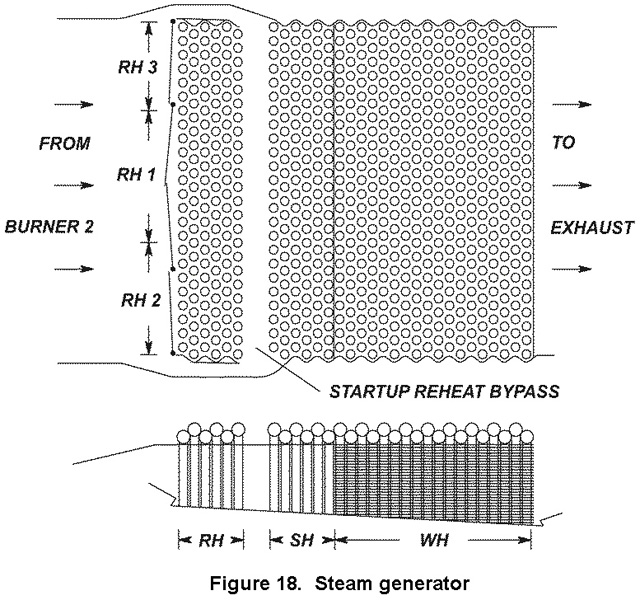

The starting sequence begins with low-temperature combustion gas flowing through the Superheater and Boiler. The Reheats are bypassed with the closure plates shown in Figure 18. The Expander and Feedpump begin turning but steam flow bypasses the Expander until vapor starts forming.

The design is adjusted to give calculated startup times of about 30 seconds for private vehicles. Longer times are acceptable for commercial vehicles. These times are for normal low-power operation, such as backing out of a driveway. Full-power capability takes 2-3 minutes, similar to warming up a conventional engine.